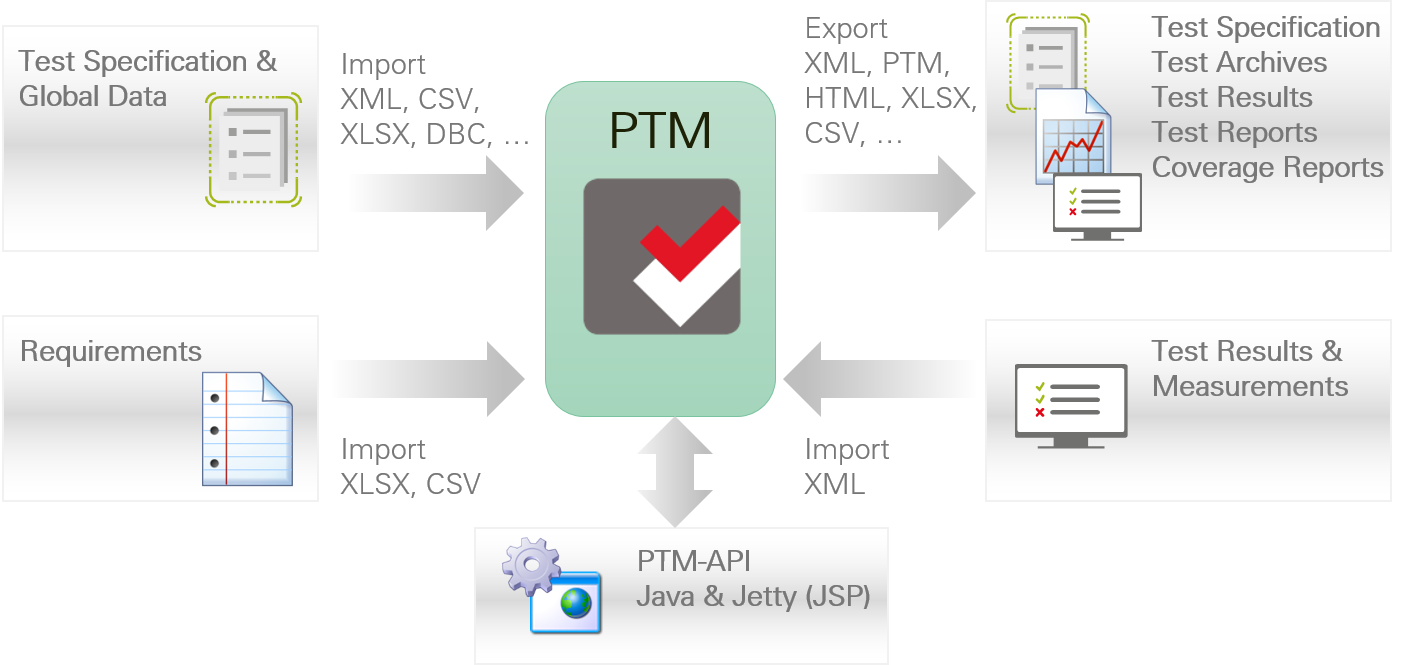

PTM is Testigence's test manager, which we developed in cooperation with our customer Daimler Truck AG since 2013. The design and implementation of PTM is based on decades of experiences regarding the testing of electronic control units and software. These experiences induce diverse requirements, large amounts of collected data and emerged processes. PTM is very flexible and supports the test processes that were developed over a long period of time by different departments working together internationally.

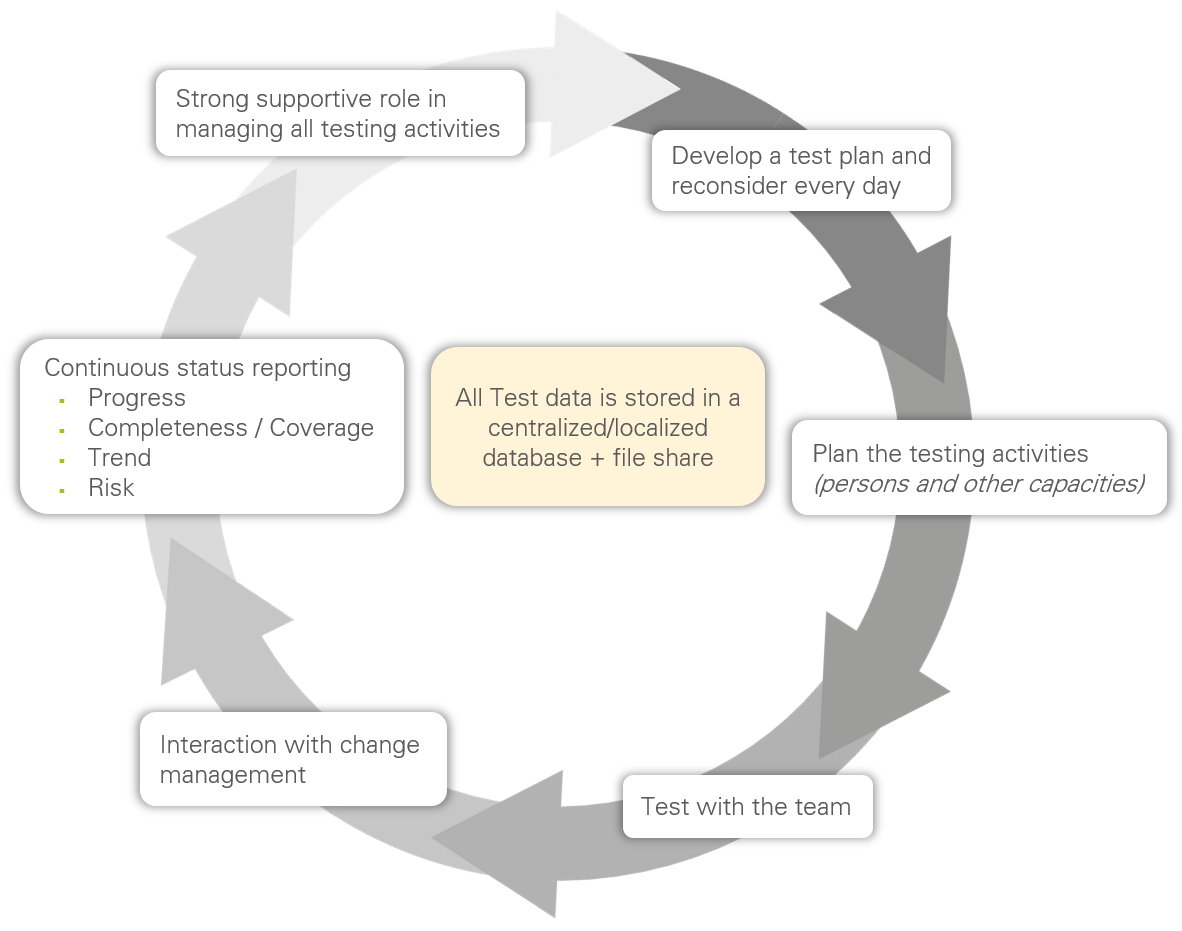

PTM supports companies in managing a big range of daily activities of test processes: Several teams need coordination in implementing test workflows that run in parallel at different stages. Thereby, all test data and logs have to be accessible and stored in a consistent, secure, and reliable way.

Special Features of PTM

Testigence focuses on the domain of automotive in order to provide tailored solutions. Electronic control systems, software for electronic control systems, and vehicle applications have special requirements for test tools - with which test cases of a test project can be managed and executed. Besides the management of measurement and diagnostic data as well as error codes, signals, and system reactions, peculiarities such as the handling of (vehicle) variants are an integral part of a test process. This data must be stored and made available in a robust and consistent way throughout the entire test process. In addition, test management tools for the automotive sector must be mobile, i.e., they must be usable without connection to a central database and support different test platforms, whether in the vehicle, laboratory or HiL.

Especially in a safety-critical area using ISO26262, traceability of requirements to test cases, documentation of test results and process support for reviews is of crucial importance to prove an ordered process.

Data security is ensured by user and rights management and the use of encrypted communication via an application server. Comprehensive test management in the vehicle area thus supplements test planning and test execution with essential security functions and aspects.

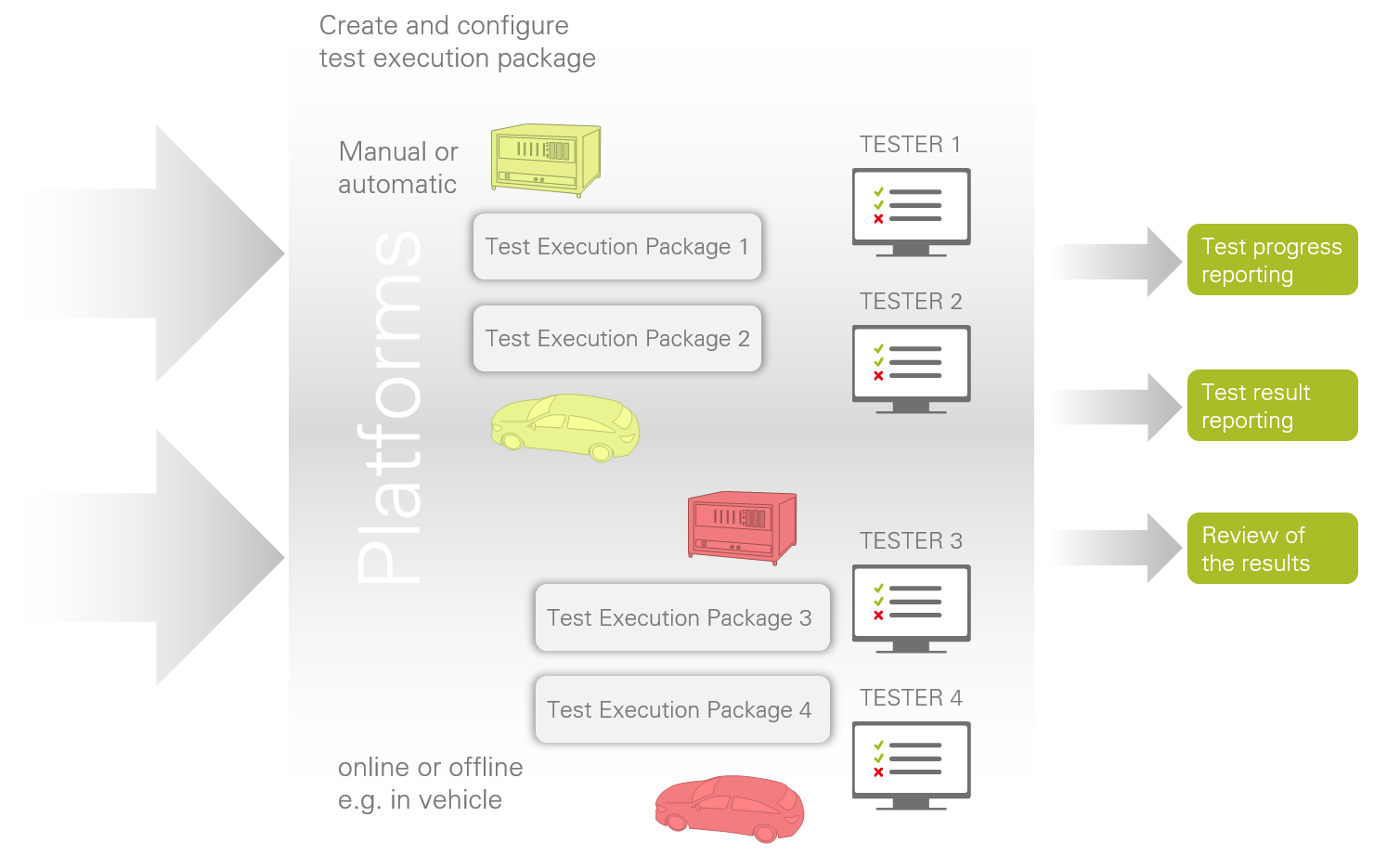

Distributed teams and companies develop automotive components worldwide. PTM users cooperate via a centralized application server while acting in different roles. Thereby, engineers act as test authors, reviewers, or testers, e.g., for specifying, refining, and releasing requirements and test specifications. Team leaders can coordinate and track the progress of teams that implement, execute (online or offline), and review tests.

In the automotive domain, test objects vary strongly regarding their type, configuration, and implementation. Engineers may want to test a single function or component simulated as software at a HiL; or they may want to check a composed system within a vehicle on the road. PTM explicitly supports functions for such use cases, e.g., to model variants of test objects, to adapt test specifications specific to variants, and to filter and configure test executions for divers platforms and targets. MiL, SiL, and HiL tests can be run automatically. Tests in a real vehicle can also be run manually.